Numerical simulation of structural stress field for Dongying Formation in Olituoz area

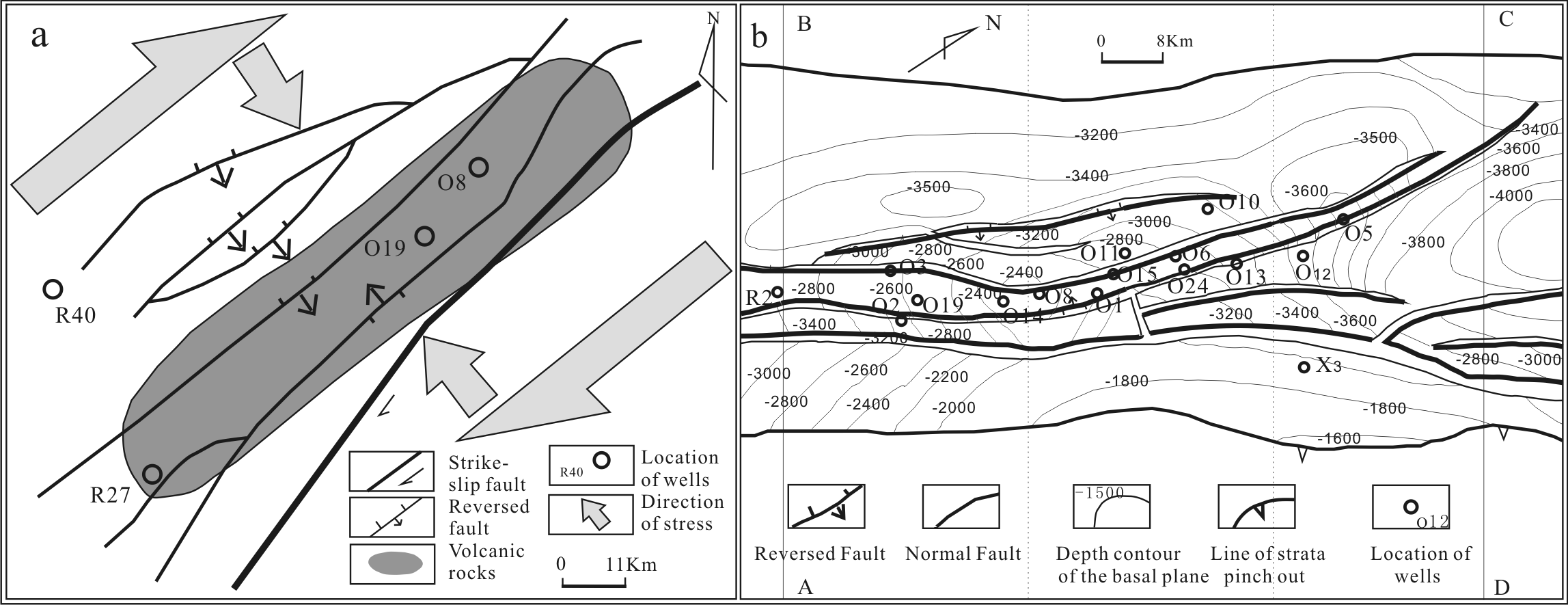

Figure 3. Mechanic model of Dongying Formation

a. Mechanic model of the study area at the end of Dongying Formation time, which is used in the simulation of the Stress field for the preparation of quantitative predicion; b. The bottom structural contour map of Es3 for the study area, which also serves as the geometric model for pre-existing fault system that strongly influences the development of structural fractures. ABCD is the simulation area of structural fractures, shown in Fig.4.

Table 3. Material Parameters for Simulation of Stress Field

| Material | Density ρ(kg/m3) | Young's Modulus E(GPa) | Poisson's Ratio ν | Cohesive Force C(Mpa) | Angle of Internal Friction φ(°) | Tensile Strength σ0(MPa) |

|---|---|---|---|---|---|---|

| Trachyte | 2500 | 30 | 0.22 | 15.5 | 41.3 | 6.68 |

| Basalt | 2700 | 35 | 0.22 | 31 | 25 | 10 |

| Lava Breccia | 2500 | 30 | 0.25 | 20 | 30 | 4.04 |

| Laval Trachy-Breccia | 2500 | 28 | 0.22 | 30 | 40 | 8 |

| Tuff | 2400 | 20 | 0.26 | 7.7 | 26.9 | 5 |

| Alternation of Sand and shale | 2400 | 30 | 0.25 | 15 | 30 | 7 |

| Sandybreccia | 2500 | 30 | 0.22 | 30 | 40 | 7 |

| Shale | 2400 | 25 | 0.25 | 20 | 40 | 8 |

| Fault | 2300 | 14 | 0.18 | 10 | 36 | Null |

Before quantitative prediction for structural fractures, simulation of stress field for Dongying Formation (Ed) time is fulfilled through ANSYS 7.0 University software (University Version). The geological model as well as mechanical model (Fig.3a) have been derived from the above study of stratigraphy and structural evolution along with the structural contour map shown in Fig.3b. The boundary conditions on the Olituoz area is the deviatoric compressive stress induced by the right-lateral strike-slip motion of Tanlu Fault system from Es3 to Ed time.

Materials of each unit for simulation are assumed to be elastic, based on the fact that the structural fractures are usually produced by brittle crack. Rock mechanical properties for simulation (Table 3) are derived from Lithomechanic measurement. As the rock samples for the whole area are limited, we have to take the data as references from previous studies (e.g. Jaeger and Cook, 1979; Sun, 1988) to provide the rock mechanical properties for the calculation. Furthermore, due to lack of data for the faults in the region, the faults are assumed to be the most common materials bearing common properties.

A more detailed description of the linear elastic finite element simulation technique can be found elsewhere (Hou et al., 2006). The results of the stress field for Es3 Formation in the Olituoz at Ed time were calculated to predict the fracture value and energy value of structural fractures for the prediction of fracture density.