3. Textures

This section shows simulations of progressive crystal growth in veins and strain fringes and discusses the developing textures.Veins

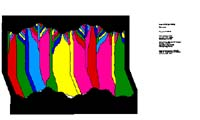

The first three simulations

(Fig. 6 a-c) with "Vein Growth" show the development of crystal textures

in one half of an antitaxial vein. The wall-rock surface is constructed

using three sinusoidal-functions with different wavelengths (200, 60 and

12 pixels) and amplitudes (120, 40 and 8 pixels). Initial nuclei have

a width of about 8 pixels. In all three simulations the vein first opens

vertically until crystals have reached a steady state texture in terms

of crystal width. Then vein opening changes by 20° towards the right

reducing the tracking-capability of the host-rock asperities (Koehn et

al., 2000). The maximum growth rate of crystals is 1.0 pixel/step in all

simulations and vein opening velocity as well as opening amount per opening

step was varied resulting in different textures.

The first simulation (Fig. 6a) shows 6000 growth stages with vein opening

of one pixel every 20th growth stage resulting in 300 vein opening events.

At the beginning of the simulation the number of growing crystals is reduced

relatively fast with only some crystals surviving. After about 3000 growth

stages crystals have reached a constant width and grain boundaries are

locked to asperities on the host-rock surface. The width of different

fibres is dependent on the distance between adjacent asperities which

is a function of the different wave-lengths that describe the initial

fracture surface. Therefore, the smallest fibres have a width of about

8 pixels and the largest a width of 40 pixels. After a change in the opening

direction some fibre boundaries loose their connection to the wall-rock

surface but most of them track vein opening.

The second simulation (Fig. 6b) lasts 3100 growth stages with the same

number of growth steps per vein opening event as the first simulation

(open every 20th growth stage) but with a larger vein-opening amount (2

pixels per opening step). With these settings, not all crystals grow fast

enough to seal the vein completely. However, crystal textures are very

similar to those of the first simulation (Fig. 6a) during vertical opening.

Once the opening direction changes grain boundaries have less tracking

capabilites as those in the first simulation.

The third simulation (Fig. 6c) lasts 4000 growth stages with an opening

of the vein of 20 pixels every 200 growth events. The tracking capability

of the asperities on the wall-rock surface is greatly reduced, even during

vertical opening, since crystal growth is not as much restricted as it

is in the first two simulations. This results in crystal textures similar

to elongate blade-like crystals that can be found in typical crack-seal

veins since crystals outgrow each other depending on their crystallographic

orientation. However a few grain-boundaries are still tracking the vein

opening and develop relatively large "fibrous" crystals. Their width is

almost completely dependent on the largest wavelength that describes the

wall-rock morphology of the vein because these asperities also have the

largest amplitudes (120 pixels).

|

Figure 6. Three simulations with ""Vein Growth" using different vein opening rates.a) Vein opening of 1pixel every 20 growth stages, b) Vein opening of 2 pixels every 20 growth stages,c )Vein opening of 20 pixels every 200 growth stages.

|

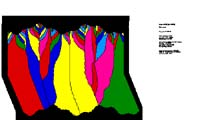

Fig. 7a shows

the simulation of a crack-seal vein with textures similar to striped bedding-veins

found in the Orobic Alps (Italy; Koehn and Passchier, 2000). The simulation

shows 1000 growth steps with a maximum crystal growth rate of 1.0 pixel/step

and a vein-opening of 10 pixels every 40 growth events. The resulting

textures show elongate crystals that grow face-controlled and are not

tracking the horizontal opening direction of the vein. The texture is

very similar to the natural example shown in Fig. 7b.

|

Figure 7. a)Simulation of crystal textures with the program "Vein Growth" to develop patterns found in striped bedding-veins from the Orobic Alps, Italy. b) Natural example of elongate crystals in a striped bedding-vein from the Orobic Alps. Sense of shear is sinistral, opening of the vein horizontal. Width of view is about 5mm. |

Strain Fringes

In

this section we present six simulations that were performed with the

program "Fringe Growth". Each figure is made up of two simulations,

one for each fringe. We reoriented the simulations relative to an external

reference frame (shear-zone boundary) assuming that fringes opened about

parallel to the extensional ISA in simple shear flow with the flow plane

oriented horizontally and a dextral sense of shear. In this case fringes

and core-object rotate relative to the external reference frame as well

as relative to each other. Note that we define relative rotation as

rotation of the core-object around its centre relative to a fringe that

is fixed in the internal reference frame (computer screen) so that core-object

and fringes have different rotation rates relative to the external reference

frame. Rotation rates for the simulations were taken from natural examples

found in a locality near Lourdes (France) using the "object-centre path

method" described in Koehn et al. (2001, see also section 4 of

this paper). Figures 8 and 9 show simulations that illustrate the effect

of internal nucleation and the effect of relative rotation between fringes

and core-object on crystal textures. Figure 10 shows a simulation of

fringes around a core-object from a natural fringe structure from a

locality near Lourdes (France) described in detail in Koehn et al.

(2001).

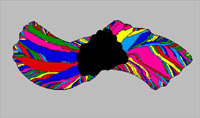

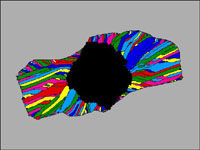

The simulation shown in fig. 8 consists of 12000 growth stages with

400 opening events. Growth rate of crystals was 1.0 pixel/step and opening

rate 1.0 pixel every 30 growth stages. Nucleation in the fringe was

turned on so that crystals could nucleate on grain boundaries on the

growth surface of the fringes. The simulation shows the development

of face-controlled fibres, displacement-controlled fibres and intermediate

fibres as well as the growth of fibre bands (Koehn et al., 2000, 2001).

Running the movie in fig. 8, it becomes evident which fibre parts are

growing face- or displacement controlled and why some nuclei develop

into fibre bands whereas others die out. The simulation also illustrates

the development of different crystal textures due to an asymmetric shape

of the core-object, since both fringes in fig. 8 rotated at the same

rates relative to the external reference frame but show different internal

textures and shapes.

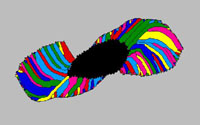

Fig.

9 illustrates the effect of rotation of core-objects (relative to their

fringes) on the growth direction of displacement-controlled fibres.

The simulation consists of 14000 growth steps with 349 fringe opening

events, a growth rate of crystals of 1.0 pixel/step and an opening of

1.0 pixel every 40 growth steps. The core-object is rotating clockwise

relative to the fringes and fringes and core-object are changing their

orientation relative to the external reference frame suddenly at growth

step 10000.

After about 8000 growth steps the core-object has rotated 40° relative

to its fringes. Displacement-controlled fibres next to the object (fibres

of the same age) in the upper part of the right fringe have a different

growth direction than those in the lower part. This is an effect of

relative rotation and shows that for these structures the growth direction

of a single fibre cannot be used for a structural analysis (Koehn et

al., 2000). Note that in this simulation both fringes are relatively

similar in contrast to fig. 8 since the core-object is almost equidimensional.

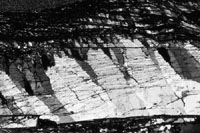

Fig. 10a shows a natural fringes structure from Lourdes (France) and fig. 10b a simulation of fig. 10a with "Fringe Growth". The simulation consists of 6000 growth steps with 300 opening events, a growth rate of crystals of 1.0 pixel/step and an opening rate of the fringe of 1.0 pixel every 20 growth steps. The close similarity in textures between the model and the natural fringe structure supports the validity of the simulations. However if we use the assumption that fringes always open parallel to extensional ISA (Ellis, 1986) in fig. 10 we have to induce sudden changes in rotation rate of fringes and core-object relative to ISA. This can have two possible causes: (1) polyphase deformation with sudden changes in ISA orientation with respect to the fringe structure (Aerden, 1996) or (2) fringes are not always opening parallel to extensional ISA (Koehn et al, 2001).

|

Figure 10. a) Natural example of a fringe structure from Lourdes. Width of view 20mm. b) Simulation of the fringe structure shown in (a)with the program "Fringe Growth" . |