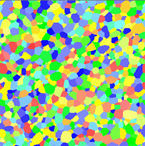

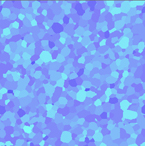

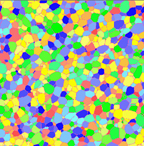

Movie 2B Movie shows the microstructural development of fabric during progressive deformation. The fabric was fine grained at the beginning of the experiment. Deformation is simple shear with strain steps (γ) of 0.05 starting at γ = 0. In this movie the attribute dislocation density is shown. Blue signifies a value of 0.001 • 1013 m-2 and red 1 • 1013 m-2. See colour bar below for the colour table used.

In simulations, areas of blue appear suddenly and change to light blue and green during progressive deformation. These areas are subgrains that have undergone recrystallization by nucleation (ELLE_NUCL; see Appendix A). Such grains had a stored energy higher than the threshold value for recrystallization by nucleation and have therefore developed into new grains with low dislocation density and high angle boundaries. In the beginning of the experiment the overall bluish colour changes to yellow/green as dislocations accumulate during progressive deformation. No areas of predominately low or high dislocation density develop.