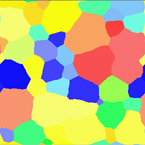

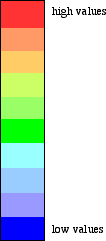

Movie 1B Movie shows the microstructural development of fabric during progressive deformation. The fabric was coarse grained at the beginning of the experiment. Deformation is simple shear with strain steps (γ) of 0.05 starting at γ = 0. In this movie the attribute dislocation density is shown. Blue signifies a value of 0.001 • 1013 m-2 and red 1 • 1013 m-2. See colour bar below for the colour table used.

In the beginning of the experiment the overall bluish colour changes to an overall yellow/green colour as dislocations accumulate during progressive deformation. Areas of blue appear suddenly and change to light blue and green during progressive deformation. These areas are subgrains that undergo recrystallization by nucleation (ELLE_NUCL; see Appendix A). Such grains had a stored energy higher than the threshold value for recrystallization by nucleation and have therefore developed into new grains with low dislocation density and high angle boundaries.

Some large grains show low dislocation densities throughout the simulation. These grains show no or only weak recrystallization at their rims (cf. Movie 1A).

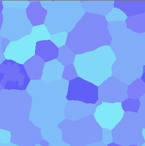

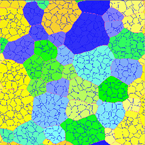

Movie 1C Movie shows the microstructural development of fabric during progressive deformation. The fabric was coarse grained at the beginning of the experiment. Deformation is simple shear with strain steps (γ) of 0.05 starting at γ = 0. In this movie the crystallographic orientation of the individual polygons is shown in different colours. Polygons with the basal plane oriented at an low angle to the flow plane are shown in blue. Polygons with the basal plane perpendicular to the flow plane are depicted in red.

In this movie at low strain the crystallographic orientation does not show a strong preferred orientation, but with increasing strain stripes of similarly oriented bluish or greenish grains develop (Fig. 2A). Areas of grains of strongly different orientation next to each other are those which have undergone recrystallization by rotation or nucleation. Those grains or grain aggregates that are bluish are those with only a low degree of recrystallization by rotation or nucleation and with a basal plane parallel to the flow plane.